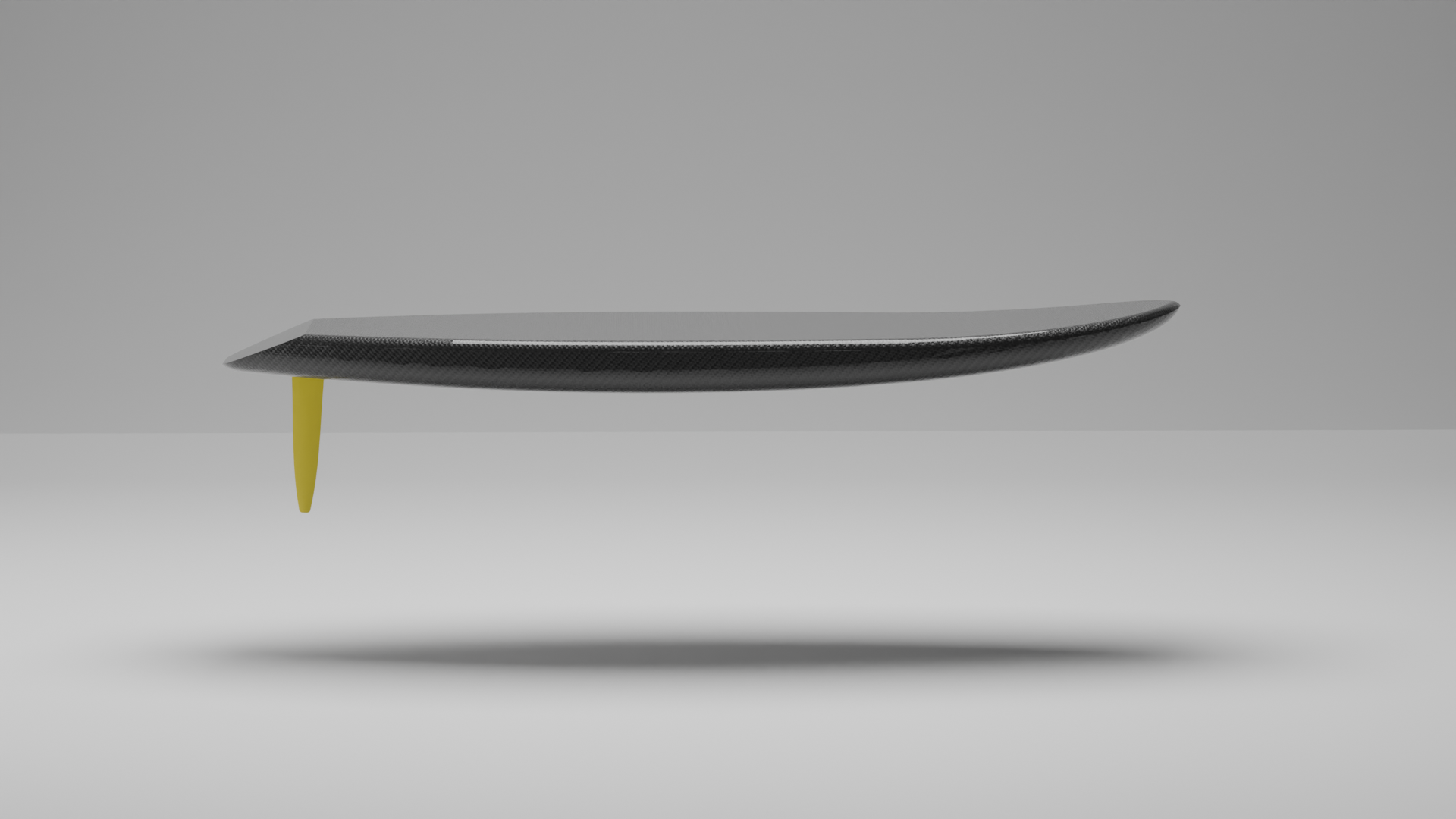

During late May and early June of 2025, I fabricated a surfboard with an included mast box using an EPS core wrapped with two layers of carbon fiber. The process involved shaping the foam and doing a layup over it. To cut the foam I used a hotwire, and I layed up the board with 3K carbon fiber and Marine grade structural epoxy.

In the process of fabricating the board, I ran into several challenges:

- During the carbon layup, creases in the carbon and a lack of tape on the underside of the board resulted in sharp fiber strands that needed to be post-processed.

- In the process of making the hotwire foam cutter, the power supply blew many times due to improper current regulation in the Nichrome wire. To address this a new power supply was purchased and cutting was performed in short time intervals to avoid stressing the power supply.

- Many visible imperfections made preparation for the lamination difficult. In hindsight, a CNC router would’ve reduced the stress involved with the hotwire.

- I attempted making a fin using infusion techniques but ran into problems with resin voids, an improper layup schedule, poor surface finish, and difficulties with consumable equipment. While I was able to achieve relatively smooth 3D printed molds, I still believe that tiny voids on the molds negatively altered the final result, which lacked rigidity. Instead, I opted for a pre-built plastic injection molded fin.

Overall, building this board was a good learning experience in composite manufacturing. I have attached some photos below outlining some of the process!

Glueing the EPS blanks together

Glueing the EPS blanks together

Shaping the board with a hotwire

Shaping the board with a hotwire

Inserting the mast box with epoxy

Inserting the mast box with epoxy

Final functional result

Final functional result